The workshop of casting hot metals.

Saturday, July 12th, 2008Have you ever experienced casting hot metals, or do you know a process how to make hot metals?

I’d got a chance to join a workshop event casting hot metals. I happened to hit the information of the event while I looked for info on hot metals. The workshop was held by Tsukiji Katsuji, means Tsukiji hot metals, however, it has little to do with Tsukiji-tai: 築地体, located in Yokohama where is near from Tokyo about thirty minutes by train.

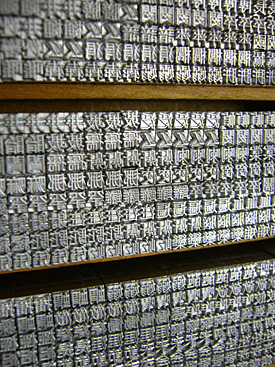

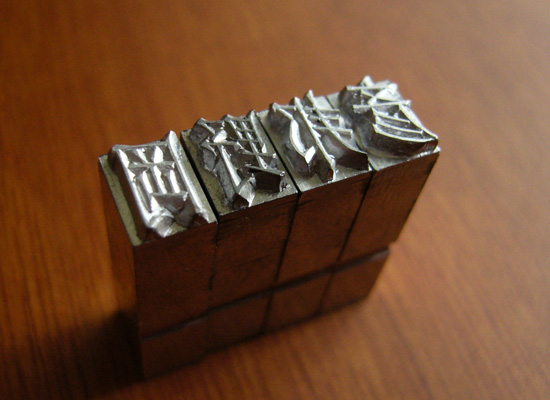

Left: The Tsukiji Katsuji. Right: Six casting machines in two lines.

I expected the building was like a factory but it was very clean like a show room for an interior furniture. I prepared a fatigue, but there seemed to be no worry about getting clothes dirty. The room had some shelfs and cases which stocked a thousands of hot metals and matrices, and on the left hand, six casting machines stood in two lines on the floor. The owner of the office, Mr. Hirakou let participants look around in the room and permitted to take photos until the time the workshop would start.

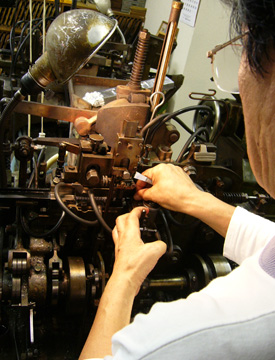

After all participants had arrived at the office, first, Mr. Hirakou started to explain the outline and history of the office. Second, a craft man of the office, Mr. Ohmatsu explained the process of casting hot metals and then demonstrated it.

Left: Mr.Hirakou explained about the stock shelfs of hot metals and matrices. Right: Mr Ohmatsu, a craft man of casting metals, explained about how to casting metals.

Left: A thausand of hot metals in the stock shelf. Right: Matrices in the box.

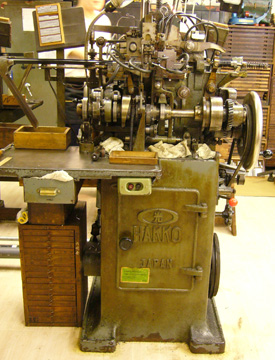

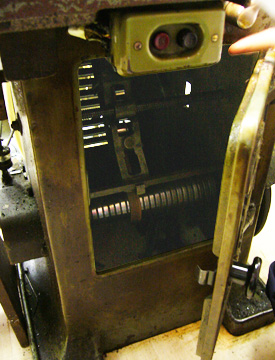

Left: The Hakko’s auto casting machine. Right: The machine had a change-speed mechanism with the belt harnessed the shaft which tapered right to left.

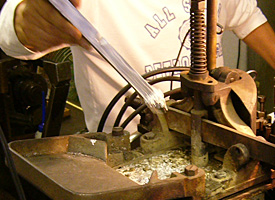

Left: The ingot made from lead, antimony and tin which came from mainly mainland China. Right: The dissolution temperature of the ingot was around 350-400 degrees. “It is very difficult to control setting temperature while summer season, because if it was not proper temper, the dissolved metal would stuck inside the machine,” Ohmatsu said. The room was sizzling. The ingot melted as soon as he put it into the machine.

Left: Ohmatsu set the matrix to the machine. Right: All participants could cast the one of letters which was included in their own name. We need to set the matrix at proper position. I thought it was good position, but Ohmastu could tell at a glance that the position was wrong, and revised it immediately.

Left: The hot metal had just made. The metal was very hot, but Ohmatsu didn’t care to have it at all. Right: The composition in a galley for a specimen book of Tsukiji Katusji.

While Ohmatsu explained every process of casting, he told us some episodes when he was a pupil of the office. The customers often came to the office at midnight and asked staffs to get hot metals. So the shop staffs needed to stay there in twenty-four seven and 365days so that they provide types to customers whenever they wanted. That’s why, the staffs couldn’t go for a trip to anywhere for a long time. All his episodes he introduced us were very interesting.

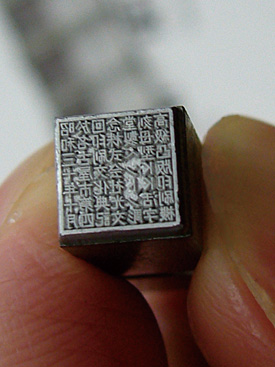

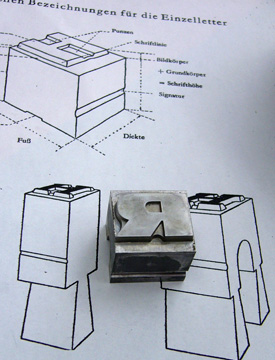

At last of the workshop, one of participants, who had owned a printing house before, showed us some hot metals he had used, which included the one casted by the Linotype machine, a huge hot metal and the unique one, which had forty-nine letters within around one centimeter square, made by the Benton machine.

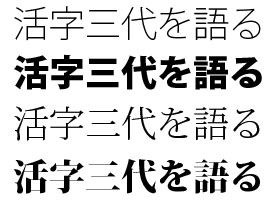

As I’m a digital font generation, I’d hardly used not only the hot metal printings but also photo type setting before. However, a magazine that features letter press and hot metals are increasing gradually. “So, designers who want to use a letter press are increasing now,” according to Hirakou.

Left: A type smaller than fingertip had forty-nine letters included Kanji and Katakana within about one centimeter, which made by the Benton punch-cutting machine. It reads that ‘昭和三十年十月於名古屋市第四回印刷文化典記念株式会社光文堂製ベントン彫刻母型KK活字高級凸版印刷機’. Right: A huge type and its explanation sheet.

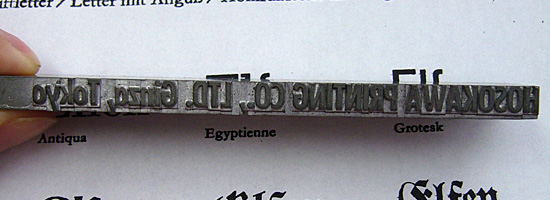

A line of type casted by Linotype machine.

The types, reads 岡野邦彦 (Okano Kunihiko), is my name, which were presented by Tsukiji Katsuji. All participants could get types of their own name each.

The workshop seems to be held on an irregular base. I’m afraid that the workshop was in Japanese only, though.